|

Step 4 |

The System Approach for Safety Oversight (SAS) Program Office is responsible for SAS. SAS is not a separate safety standard and does not impose additional requirements on certificate holders. SAS provides aviation safety inspectors with standardized protocols to evaluate certificate holder programs required by regulations to be approved or accepted. It is an automated approach to determine that a certificate holder is able to operate safely under the prescribed regulations and standards.

The configuration of an operator's operating profile is determined by their configuration data (vitals) and desired operations specifications. The SAS process produces a scoped operating profile along with DCT's. The trigger for this process is an initial certificate or a change request for:

|

|

|

The scoped operating profile is used by the Data Collection Tool (DCT) to generate questions whose response determines compliance with the regulations and guidance. Knowledge of this process and policy is fundamental to understanding SAS automation and a successful outcome. SAS, along with the automated analysis within DCT, supports the subsequent approval or acceptance of new or revised manuals; or, the issuance of new or revised operations specifications.

There are five steps in the SAS process:

Operators are mainly involved in Configuration and Data Collection.

Configuration: The Configuration is performed by the FAA principal inspectors with the operator to enter the vitals (operator specific data) the operator's profile.

Data Collection: Data Collection is performed by the operator, much like a compliance statement, to identify compliance and the location in the manual system where the procedures or records are specified. It is an automated process. The data is verified by the FAA principal inspectors. Success results in acceptance, approval, or issuance of the desired item.

Initial Certification: Submit an application package to the certificate-holding district office (CHDO) through the use of the SAS external portal. The applicant will have access to Module 1 for configuration data and to Module 4 for Element Design DCTs (ED DCTs). The CPM will be notified of configuration change requests as they are submitted through the SAS external portal.

FAA-Initiated Change: The FAA may amend OpSpecs or require program revisions when safety in the public interest requires such action. Amendments or revisions can result from significant changes to the certificate holder’s operating environment or safety concerns. If the certificate holder does not use the SAS external portal, the PI must enter the configuration data into the automation with a change request.

Certificate Holder-Initiated Change: The request may be submitted in a letter form or through the use of the SAS external portal. If the external portal is used, the certificate holder will have access to Module 1 for configuration data and to Module 4 for ED DCTs (if required). Regardless of who initiates the change, the certificate holder must submit documentation for the FAA to evaluate the impact of the change.

Although the use of the SAS external portal is not required for existing certificate holders, it is highly recommended. If the certificate holder cannot or does not use the SAS external portal, the PI must enter the configuration data into the automation with a change request.

Revisions may be required to the operator's manual system and the process repeated.

After the principal inspector or certification program manager approves or accepts the change, the operating profile is considered finalized and the vitals are updated. However, if the change affected a change in operations specifications, then the principal inspector or certification project manager will need to update the operations specifications using WebOpss. Once all the changes have been made, the principal inspector or certification project manager should validate the changes in the operating profile and the configuration data.

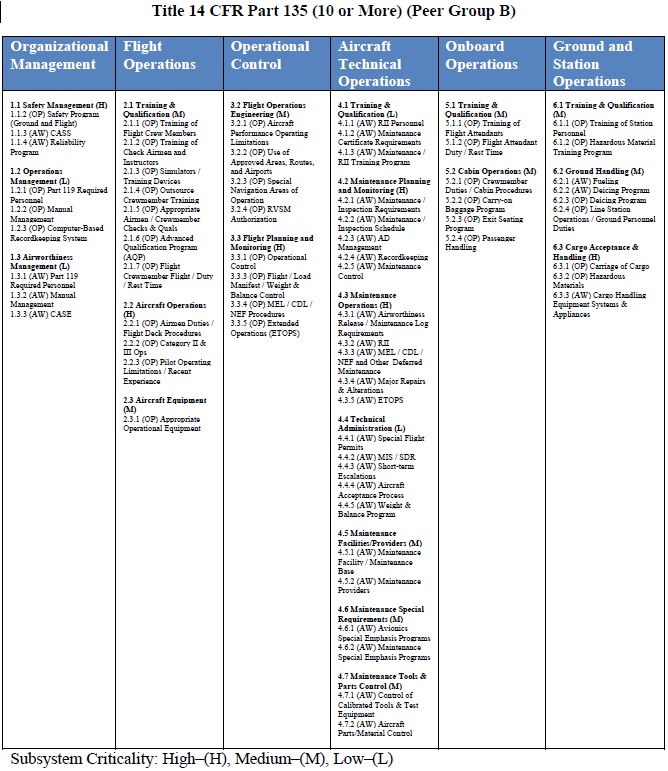

The scope of data that is collected by the Data Collection Tool can be extensive. The data is organized into subsystems (categories) called the Master List of Functions. The DCT generates between 30 and 100 questions per subsystem. An example of the Master List of Functions for a Part 135 10 or more operator is presented below. A full 135 operator with 9 or less passenger seats has many of the same subsystems but fewer questions per subsystem.

An example of an ED DCT set of questions for a small 10 or more operator is presented below. The number of DCT's associated with this operator is 37. Not all the DCT's in the Master List of Functions are applicable because of the small size and scope. The maximum number of questions for a DCT associated with this operator is 138. It is possible to have well over 500 questions for a full 135 10 or more operator.

The operator must answer Yes, No, nor NA in the Answers column. The operator must reference the location in the operator's manual system in the right column. Additional questions may be generated based on an operator's response. Upon successful completion, the FAA POI or CPM will verify the operator's answers. The analysis, assessment, and action is performed by the FAA POI or CPM. A successful outcome results in accepting or approving a manual or issuing operations specifications. The estimated time for an experienced operator to complete the DCT's is about 250 hours (9 or less operators), 500 hours (10 or more), and 1,000 hours (more than 19).

Read on...